The pursuit of optimization in logistics remains a constant challenge. Supply chain workers, freight handlers, and warehouse operators always look for cutting-edge solutions capable of enhancing productivity and reducing errors. Lately, augmented reality in logistics has found application in the management and organization of workflows and has been radically transforming the industry as we know it.

The number of supply chain leaders planning to implement AR/VR technologies has been steadily increasing over the past few years. Researchers indicate that the use of AR in logistics and supply chain management is set to grow at an impressive CAGR of 30% by 2030.

In this blog, we explore how augmented reality revolutionizes logistics operations, empowers workers, and enhances overall productivity. We will then delve into real-world use cases, showcasing how industry giants have seamlessly integrated AR technology into their workflows, leading them to achieve remarkable success.

But first, let’s take a brief overview of the issues and challenges currently plaguing the logistics sector.

Current problems in the logistics sector

Warehouse management is a multifaceted task that requires handling a diverse range of interconnected elements.

Many supply chain companies grapple with various challenges, such as:

- Manual operations causing avoidable delays: Reliance on manual operations leading to unnecessary time lags, and inefficiencies in workflows.

- Frequent errors in order fulfillment: Outdated systems contributing to consistent mistakes in assembling orders accurately, leading to customer dissatisfaction and additional costs.

- Higher costs and efforts to maintain obsolete systems: Outdated management systems demand more money, effort, and resources for upkeep and maintenance from logistics providers.

- Difficulty in organizing returns: Handling returns becomes a cumbersome task when the warehouse administration procedures are not optimized, resulting in longer processing times and customer discontent.

- Disruptions due to labeling errors: Inaccuracies in labeling disrupt operations, contributing to a sluggish overall operation.

Conversely, the incorporation of augmented reality in the logistics industry has the capacity to revolutionize the procedures related to the transportation, supervision, and control of goods.

By superimposing digital data onto the physical surroundings, augmented reality solutions are opening up avenues for remarkable progress in enhancing visibility, precision, and collaboration in the domain of supply chain activities.

Understanding AR

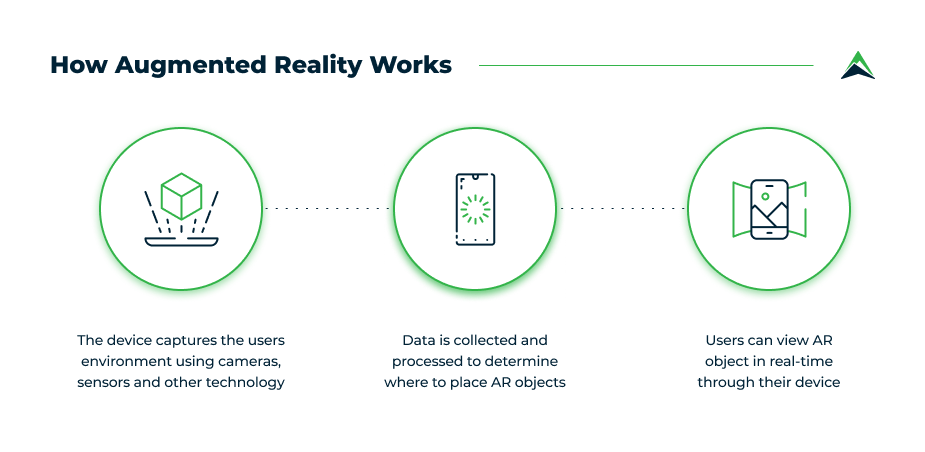

Augmented Reality (AR) technology enriches the real-life surroundings by superimposing digitally-generated sensory information like audio, graphics and virtual elements onto the user’s real-time view. This captivating user experience is reached via excellent interconnection of hardware, software, and sensors.

Once the system understands the user’s environment, it integrates the virtual content into the real-world view displayed on the device’s screen or through AR spectacles. This virtual content can include 3D objects, text, images, animations, and more, which appear to coexist and communicate with the physical world.

In essence, AR crafts an engaging and immersive experience that elevates users’ perception of reality. Its versatile applications span across various industries, encompassing gaming, education, training, healthcare, and industrial scenarios, among others.

The applications for AR in logistics range from order picking and fulfillment to collaborative decision making. Below, we will delve deeper into how implementing AR in logistics improves the processes throughout the supply chain.

The Pros of using AR in supply chain

Integrating augmented reality offers a wide array of substantial business advantages, transforming traditional practices and elevating overall efficiency.

Here are some of the key benefits:

Enhanced productivity

AR applications deliver real-time, context-sensitive information to workers, optimizing task execution and reducing time spent searching for items or navigating the warehouse. These apps streamline workflow leading to faster order fulfillment and improved productivity.

Better accuracy

The workflows guided by AR technologies minimize human errors in picking and packing by providing visual cues and step-by-step instructions. This reduces the probability of mispicks and shipping errors, resulting in higher customer satisfaction and reduced returns.

Employee training

AR software facilitates employee training. New workers can quickly grasp complex procedures through interactive simulations, shortening the learning curve and enhancing workforce productivity.

Inventory control

Applying AR for warehouse management facilitates the immediate tracking of inventory, guaranteeing precise stock level monitoring and minimizing the possibility of stockouts or excess stock scenarios. This contributes to improved inventory management and enhanced cost efficiency.

Security and compliance

AR applications in logistics include overlaying safety guidelines and compliance protocols directly onto warehouse environments helping prevent accidents and ensuring that workers adhere to safety regulations.

Remote instructions

Experts can provide remote assistance to on-site workers by superimposing instructions and annotations on their view. This capability is especially valuable in troubleshooting and repairs, minimizing downtime, and increasing equipment lifespan.

Enhancing final leg delivery

Navigation tools grounded in augmented reality can optimize route planning and live monitoring for delivery drivers. This results in expedited and more effective final leg deliveries, ultimately elevating customer satisfaction.

Data analytics

Real-time data visualization allows managers to access current performance metrics, analyze trends, and make informed decisions, helping in pinpointing bottlenecks, optimizing workflows, and achieving continuous improvement.

Enhanced collaboration

AR facilitates real-time communication among team members. Employees can share information and collaborate on tasks, regardless of their physical location, leading to better coordination and problem resolution.

Competitive advantage

Early adoption of AR in warehouse management can provide businesses with a competitive edge. Implementing innovative tech demonstrates a commitment to efficiency and customer satisfaction, potentially attracting more clients and partners.

Reduced training costs

AR uses in logistics include training solutions that can reduce the need for physical training resources, leading to cost savings in the long run. Employees can access interactive training modules on devices, minimizing the need for dedicated trainers and physical training facilities.

On the whole, implementing AR solutions in logistics and warehouse administration procedures leads to heightened accuracy, swiftness, and adaptability. As technology continues to advance, the advantages of augmented reality in supply chain management are expected to become even more conspicuous.

Top 14 augmented reality (AR) applications in logistics

The logistics sector is witnessing a multitude of applications for augmented reality, revolutionizing operational practices and yielding advantages for both companies and customers.

Below are key instances of how to use augmented reality in logistics:

1. Streamlined order picking and fulfillment

Implementing Augmented Reality in logistics aids warehouse personnel in accurately and swiftly locating and selecting items. By overlaying digital data onto physical objects, AR guides workers to the correct shelves and products for efficient order completion.

2. Enhanced navigation

Augmented reality provides real-time navigation and guidance within warehouses, helping employees determine the quickest and most effective paths to specific destinations or items.

3. Dynamic inventory management

Through applications of AR in warehousing, the staff can visualize real-time inventory levels and stock placements. This empowers rapid identification and monitoring of inventory, leading to fewer errors and enhanced overall stock control.

4. Loading and unloading assistance

Augmented reality can help in loading and unloading trucks and containers by projecting virtual markers or labels onto packages, ensuring correct placement and organization.

5. Delivery route enhancement

AR-based navigation tools offer delivery drivers up-to-the-minute route details, traffic alerts, and precise delivery instructions, enhancing the efficiency and punctuality of deliveries.

6. Final leg delivery support

Assisting delivery personnel in locating specific delivery addresses, especially in complex urban environments, ensuring accurate and timely deliveries.

7. Shipment tracking and visualization

By leveraging AR applications, customers can access real-time package tracking and dynamic visualizations of the shipping process, elevating their overall experience.

8. Instructing and onboarding

AR proves invaluable in training newly-hired workers by offering simulations and hands-on learning instructions for various logistics tasks, ensuring efficient and effective onboarding processes.

9. Maintenance and support

Assisting maintenance technicians by offering visual instructions and data overlays during equipment repairs or inspections, minimizing downtime, and enhancing the precision of maintenance tasks.

10. Remote troubleshooting

Facilitating remote support and cooperation between field workers and experts. Workers in the field can use AR to share their perspectives with off-site experts, who can then provide real-time instructions.

11. Augmented reality packaging

Businesses can use AR in logistics to create engaging packaging experiences for customers, offering additional information, product demonstrations, or promotional content.

12. Quality control and inspections

Augmented reality can aid quality control procedures by offering visual overlays to inspectors, instantly pinpointing defects or inconsistencies.

13. Deeper customer involvement

AR applications deepen customer engagement through features like interactive product catalogs, virtual showrooms, or campaigns that utilize augmented reality for marketing.

14. Cooperative administration

Augmented reality enables collaborative decision-making within warehouse operations by enabling multiple users to simultaneously access and engage with digital information.

These highlighted use cases vividly demonstrate the transformative influence of augmented reality in the supply chain realm, amplifying efficiency, accuracy, and customer satisfaction. As AR technology advances, a wave of innovative applications is on the horizon, poised to propel the logistics sector to unprecedented heights.

Read also: 7 Ways Augmented Reality Transforms Manufacturing

Real-life AR examples in logistics

So, how can augmented reality revolutionize logistics? Numerous companies have embraced AR to refine diverse aspects of their supply chain and delivery processes.

Below are some compelling examples:

- DHL: A prominent global logistics and shipping firm has seamlessly integrated AR smart glasses into their procedures, optimizing order selection and streamlining warehouse operations. The smart glasses provide visual directives to staff, precisely directing them to the correct spots and items for fulfilling orders. This innovative approach has led to notable advancements in precision and efficiency within their facilities.

- UPS: The United Parcel Service has been testing AR technology for driver training and navigation. They’ve harnessed AR headsets to furnish delivery drivers with visual cues and directions, amplifying the accuracy and pace of their deliveries.

- Walmart: Walmart has experimented with augmented reality in warehousing and inventory management for replenishing their stores. Augmented reality has been deployed to monitor inventory levels, identify products on shelves, and guide employees in restocking items with efficacy.

- XPO Logistics: A global provider of transportation and logistics services, XPO Logistics has seamlessly incorporated AR into their warehouses to heighten order-picking precision and efficiency. AR headsets are employed to direct workers through optimal routes and furnish real-time instructions for fulfilling orders.

- Geodis: This supply chain enterprise has harnessed smart glasses to optimize warehouse functions. These smart glasses assist pickers in identifying items, verifying orders, and curtailing the time required for the order selection process.

- Maersk: A container shipping company has harnessed augmented reality solutions to offer customers an interactive container-loading experience. AR applications enable customers to see how to optimize container packing, ensuring effective utilization of space.

These instances vividly showcase AR’s applications in supply chain management and diverse logistics-related functions and industries. As technology evolves, we can anticipate more companies adopting extended reality solutions to tackle logistics challenges head-on.

Looking for AR solutions in logistics?

We at Eastern Peak can help you unlock the potential of AR in the logistics sector and create custom software solutions using AR technology that cater to your business needs.

Final thoughts on implementing augmented reality in logistics

The array of advantages offered by augmented reality has the potential to refine your workflows, amplify efficiency, and heighten client satisfaction. Developing an AR application tailored for logistics warehouses opens the door to improving order fulfillment, optimizing stock control, and enhancing last-mile delivery processes. This culminates in lowered costs and heightened productivity.

AR’s diverse applications, from order picking to last-mile delivery support, demonstrate its power to revolutionize supply chain management. With industry giants like DHL, UPS, and Walmart already successfully integrating AR, making it clear that the future of logistics is augmented.

However, companies also encounter several challenges during the implementation process. A primary challenge lies in the initial cost of integrating AR technology into established operations, encompassing both hardware and software expenses.

Moreover, achieving immaculate integration with current warehouse management systems and adequately training employees demands considerable time and effort. Additionally, privacy and data security concerns emerge when employing AR devices that capture and process real-time data within the logistics environment.

To surmount these obstacles and fully unlock the potential of AR in the logistics sector, companies need to engage an experienced tech partner to ensure meticulous planning, investment, and ongoing support.

Each company, however, will have its own set of unique needs which can be met by creating a tailored app for AR warehouse. If you are looking to build a custom AR app and aren’t sure where to start, reach out to us for a free consultation!

Read also: